|

|

|

Temperature Control in indirect system

Last Post 25 Aug 2014 10:04 AM by sailawayrb. 21 Replies. |

Sort:

|

|

Prev Next Prev Next |

You are not authorized to post a reply. |

|

| Author |

Messages |

|

tejaycar

New Member

Posts:11

|

| 19 Aug 2014 07:19 PM |

|

First, thank you so much for your thoughts and ideas. I really appreciate it.

The very short version

When using a heat exchanger of a Polaris water heater, what's the best way to control the supply temperature of my radiant floors.

The longer version

Background

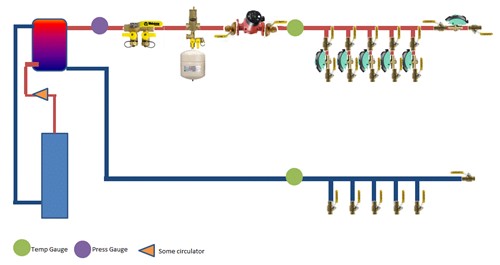

I'm building out a retrofit radiant floor system for a 3700 sq ft home with a boiler demand of ~90,000 BTU. My plan is to use a 150k Polaris to provide both DHW and radiant heat. I'm planning to run the DHW off the Polaris directly, and use a heat exchanger to run the radiant system. I think I've got the mechanical room figured out with one exception. How do I control the temperature of the system loop? You can see my current plan (Sans any temperature control)

I'm interested in any feedback, but especially:

- How do I control the temperature of the system loop.

- Did I do something stupid?

- Is a zone control unit worth the extra cost, or should I just wire it up directly to the zone valves.

- Are the pressure and temperature gauges in the best place, or is there a better arrangement.

With regards to the temperature control, I'd love to do outdoor reset, but I'm on a tight budget. If there is an option that allows me to add outdoor reset later, without tossing any parts, that would be great. Or, if I can do outdoor reset for about the same cost, that would be even better. |

Attachment: first_cut.GIF Attachment: first_cut.GIF

|

|

|

|

|

|

Dana1

Senior Member

Posts:6991

|

| 20 Aug 2014 11:38 AM |

|

How did you determine the heat load? A true heat load of 90,000 BTU/hr seems pretty high for a 3700' home. Assuming you have at most 3000' of usable radiant floor that's 30 BTU/ft 2, which can be hard to hit at condensing temperatures in retrofits (unless it's WarmBoard or gypcrete or something?) If the heat load is actually more like half that (likely), you may have a chance. A room-by-room heat load calculation and the amount/type of radiant per room is necessary to determine the required water temperatures. A bypass branch with a thermostatic mixing valve with outdoor reset could be used if you're trying to maximize comfort and minimize temperature swings. But a cheaper mixing valve that you tweak by hand is probably going to be fine too. Start out with the temp tweaked to say, 110F at the output of the valve (100F if WarmBoard) and bump it up only if it's not keeping up. Cooking up a design and locking into system features without doing at least the napkin math on all aspects of the system could lead you into some very expensive errors, a completely disfunctional system or discomfort at the temperature extremes. Hydronic heating design is more than just a plumbing project. |

|

|

|

|

Blueridgecompany.com

Advanced Member

Posts:656

|

| 20 Aug 2014 11:46 AM |

|

nice illustration,

you're missing a pump between the Polaris and heat exchanger, (bronze or stainless has to be potable rated), look at a taco 005, 007, can be switched with the zvc control. Might want to look at heat exchanger size/flow requirements to make heat loss as well related to this portion of your system.

I would prefer an auto feed (back flow prevention/pressure reducing valve in place of the webstone valve you have.

System pump could be a Taco bumble bee set on temperature set point, it will then vary flow based on temp and also on zones calling for heat.

You may need more than one system pump depending on number of pex circuits and length of pipe. Head and flow.

Alternately a 3 way mix valve on system side and Grundfos Alpha pump.

Dan |

|

| Dan <br>BlueRidgeCompany.com |

|

|

Dana1

Senior Member

Posts:6991

|

| 20 Aug 2014 03:43 PM |

|

Dan the Polaris side pump is there- the legend for the orange triangle icon reads "some circulator". |

|

|

|

|

sailawayrb

Veteran Member

Posts:2272

|

| 20 Aug 2014 03:47 PM |

|

Like Dana suggested, start with a room-by-room heat loss analysis followed by hydronic radiant design analysis to properly determine the required supply temps, flow rates and pump:

Borst Heat Loss Analysis Software

Borst Hydronic Radiant Floor Heating Design Software

Why a Polaris versus say a Navien combination condensing boiler?

Navien

|

|

| Borst Engineering & Construction LLC - Competence, Integrity and Professionalism are integral to all that we do! |

|

|

jonr

Senior Member

Posts:5341

|

| 20 Aug 2014 04:29 PM |

|

Note that your design is always producing hot (say 130F) water, even when all you might need is 90F and less water for radiant heating. This isn't ideal in terms of condensing boiler efficiency. |

|

|

|

|

tejaycar

New Member

Posts:11

|

| 20 Aug 2014 05:43 PM |

|

Dana,

Thanks for the thoughts, and I totally understand. Let me explain the 90,000, and hopefully put everyone's minds at ease that I'm not totally nuts.

First, that is the boiler load, including backloss, etc. I worked it up room by room with RadiatnWorks Pro and was very conservative to ensure I didn't under-design it. I figured, worse case, I install way too much pex and turn down my temps. I've got Radiant Works calculating it with a design temp of 115 and a Delta T of 15. We only have about two weeks a year of design level weather, so I should be able to run quite a bit lower temp most of the winter.

I had considered a setpoint mixing valve initially that I could swap out for a setback one later. My only issue with that was uncertainty regarding the setup of the loop. Do I need a third circulator between the heat exchanger and the mixing valve?

I'll also add a few other design numbers in a general response. |

|

|

|

|

tejaycar

New Member

Posts:11

|

| 20 Aug 2014 06:05 PM |

|

Dan,

I'd considered the bumblebee, but I'm concerned that if my water heater is at 130 and my "need" is closer to 100, that the bumblebee might not be able to slow down enough, especially if only one or two zones are calling, to keep my temps low. If you have experience to the contrary, that certainly has the advantage of wrapping my temperature control and pump all into one.

As far as the system side mixing valve is concerned, I would need a 4 way valve to comfortably hit 12GPM. I was looking into those, and almost added one to the diagram, but every schematic I found for it included a pump between the heat source and the mixing valve, in addition to the one between the mixing valve and the alpha.

Finally, can you tell me more about the auto-feed? That's not something I've seen in my reading yet.

sailawayrb,

I guess I'll reverse the question on you. Why a Navien vs. a Polaris? I settled on the Polaris after a lot of research several months ago, so I can't recall all the reasons, and I'm happy to hear a contrary opinion. If memory serves me right, the main reason was the cost of a boiler + storage tank. As jonr points out, the current design doesn't work well with a condensing boiler, but I could certainly invert it with the heat system running off the boiler and the DHW running from an indirect tank. Is there a better approach that lets me hit condensing temperatures while being cost competitive? I also liked the simplicity of the hot water heater system. I'm an engineer and talented handyman, but I'm still a DIYer, and the more I read about boilers and the many ways you can break them the more nervous that made me.

Again, thanks to all of you for your input. |

|

|

|

|

tejaycar

New Member

Posts:11

|

| 20 Aug 2014 06:07 PM |

|

Ok, so a few more design numbers. You guys are digging deeper than I'd expected, and I really appreciate that.

- 6 zones with 23 loops ~200ft per loop

- 12.4 GPM total flow

- 5.6 ft of head (not including the mechanical room)

|

|

|

|

|

sailawayrb

Veteran Member

Posts:2272

|

| 20 Aug 2014 07:13 PM |

|

I was not suggesting a Navien in lieu of a Polaris, although the Navien does provide both DHW and HR space heating capability without a tank. I was just wondering why a Polaris over the multitude of other choices.

Without accurately knowing your heat loss, I couldn’t venture a guess if you can hit efficient condensing temps. However, for buildings that are properly insulated for the climate, this isn’t typically challenging.

|

|

| Borst Engineering & Construction LLC - Competence, Integrity and Professionalism are integral to all that we do! |

|

|

tejaycar

New Member

Posts:11

|

| 20 Aug 2014 09:41 PM |

|

I had not actually seen the Navien before, and I'm quite interested in it. My main requirements were:

- High Efficiency

- Cost

- Combination unit

- I didn't want a separate storage tank (mostly due to cost)

- Simplicity to design and operate

The Navien seems to match or exceed the Polaris in most ways. Assuming I can maintain a temperature of 115 or less, what would be the major reasons to avoid a Navien? Are there other combi solutions that I should give serious consideration to?

As a side note, I'm a bit confused by the outputs I'm getting from RadiantWorks PRO. If I add the heatloss from all rooms, I get a total of 56k BTU/H. The Mechanical Summary lists a "Boiler Load" of 93271 BTU/h, and if I add up the "Total Required(BTU/h)" from each zone, I get 60K. I'm guessing that the difference between heatloss and "total required" is estimated loss in the home runs between the heat source and the zones. I believe the delta between "boiler load" and "Total Required" is backloss on the radiant system itself. Does that sound correct? |

|

|

|

|

sailawayrb

Veteran Member

Posts:2272

|

| 21 Aug 2014 08:28 AM |

|

We like and use the Navien in some applications, however, we try to avoid advocating one brand over another unless there is solid data to do so. And before considering the brand of boiler, one should also consider the broader merits of using a heat pump versus using a boiler. In other words, there are many factors to consider when selecting the heat source and it is unlikely that there is one solution that is optimal for all applications.

I am not familiar with RadiantWorks PRO. When you design a HR heated floor, you do have to breakout the floor downward heat loss and bookkeep it separately from the remaining room heat loss. Perhaps exercise our free DIY HR floor heating design software (link was previously provided) to compare and validate your design. Our software is based on John Siegenthaler’s Modern Hydronic Heating design methodology. BTW, John’s book is a great design reference as well.

All of our HR floor heating designs only require a heat source supply temp of 90F or less. This is easily achieved with a slab or thin-slab HR floor emitter that isn't covered with carpet, hardwood flooring, or other high R-value covering in new building construction that is properly insulated for the climate. |

|

| Borst Engineering & Construction LLC - Competence, Integrity and Professionalism are integral to all that we do! |

|

|

jonr

Senior Member

Posts:5341

|

| 21 Aug 2014 10:07 AM |

|

I'd take a good look at a modulating, condensing boiler with OR for the radiant floor and a standalone gas water heater for DHW (@ ~130F for legionella if it has a tank). You save some on the heat exchanger/pump and you save perhaps 7% by the boiler running at the lowest possible temps. Should also be less HE deposits (the majority of the btus are generated in a closed loop system). |

|

|

|

|

Dana1

Senior Member

Posts:6991

|

| 21 Aug 2014 11:13 AM |

|

Posted By tejaycar on 20 Aug 2014 09:41 PM

I had not actually seen the Navien before, and I'm quite interested in it. My main requirements were:

- High Efficiency

- Cost

- Combination unit

- I didn't want a separate storage tank (mostly due to cost)

- Simplicity to design and operate

The Navien seems to match or exceed the Polaris in most ways. Assuming I can maintain a temperature of 115 or less, what would be the major reasons to avoid a Navien? Are there other combi solutions that I should give serious consideration to?

As a side note, I'm a bit confused by the outputs I'm getting from RadiantWorks PRO. If I add the heatloss from all rooms, I get a total of 56k BTU/H. The Mechanical Summary lists a "Boiler Load" of 93271 BTU/h, and if I add up the "Total Required(BTU/h)" from each zone, I get 60K. I'm guessing that the difference between heatloss and "total required" is estimated loss in the home runs between the heat source and the zones. I believe the delta between "boiler load" and "Total Required" is backloss on the radiant system itself. Does that sound correct?

If you are in stalling the boiler in a shed and the home-runs are outside the house, and the radiant is over an unconditioned ventilated crawlspace, sure. If it's all fully inside of conditioned space, those losses aren't losses, since any losses between the boiler and the zone calling for heat accrue to the adjacent zones, reducing the loads on those zones. Distribution losses and radiation backlosses that occur inside the conditioned space are not fully lost, and do not add to the boiler load. A heat load of 56,000 BTU for a 3700' home is a credible number (about 15 BTU/hr-ft 2), but it's still on the high side, and it may be that you've played the numbers game of being too conservative out of a concern for it not keeping up, putting a biased thumb on the scale. This is a common newbie error (and a lot of pros too) that leads to overdesign/oversizing the systems, higher up-front cost, and potentially lower system efficiency. Use realistic indoor design temps 68-70F, not 72-74F unless you intend to keep EVERY room in the house at that higher temp 24/365, and nothing colder than the 99th percentile bin for an outside design temp. Even though it probably gets 5-10F colder than that at least once every season, it doesn't matter. Even if you designed and controlled the system EXACTLY for the load at the 99% outside design temp, it has to stay more than 10F below that for hours before you lose enough ground that it's a comfort issue- the house and it's contents have substantial thermal mass. Most heat load calculation tools inherently bias toward the conservative by more than 10%, and the only way to truly right-size the systems is to be fairly aggressive rather than conservative on the design assumptions. If you've inserted a conservative bias in your data entry to come up with 56K, your real heat load of your house is probably something like 45-50K, which would make a 90K heat source 2x oversized for the actual load. Most code-min houses half the size of yours come in at ~12 BTU/hr-ft 2 these days, and bigger houses typically come in lower than that. Most heat load tool defaults on infiltration/ventilation losses are insanely high, and if your house truly leaks that much air it's going to be worth spending the money for air-sealing anyway. IRC 2012 code max leakage of 3 air exchanger per hour @ 50 pascals does not translate into a huge heat load for hydronic heating systems. If your house leaks more than that it's usually fairly easy to retrofit any home built with 4x8 sheathing & wallboard to those levels, if a bit harder for plank-sheathed antiques with cracking plaster & lath. Oversizing the radiation isn't necessarily a problem, but oversizing the heat source is, especially when you've micro-zoned the hell out of it with low-mass radiation. The min-fire output of low-mass combi-boilers like the Navien is a large multiple of the design heat loads of your smaller zones and in heavily micro-zoned system you can easily short-cycle it to low efficiency & early death on zone calls even if it's min-fire output is below your average mid-winter load. |

|

|

|

|

tejaycar

New Member

Posts:11

|

| 21 Aug 2014 11:36 AM |

|

Dana,

So, correct me if I'm wrong, but it seems like all of the combi boilers I've looked at will be dramatically oversized if I want a reasonable 5GMP+ DHW availability. With a combi water heater, like the polaris, the cycling of mico-zones seems less of an issue due to the thermal mass of the stored water in the tank. Is that accurate? Given what you're seeing here, is a 130K Polaris a good fit, or are there still problems there?

Thanks,

Tejay |

|

|

|

|

jonr

Senior Member

Posts:5341

|

| 21 Aug 2014 01:28 PM |

|

Design for some flow to most zones all of the time (ie, bypass) with the zone valves adding some additional flow as needed and you won't have micro zoning problems that require a buffer tank. |

|

|

|

|

Dana1

Senior Member

Posts:6991

|

| 21 Aug 2014 01:40 PM |

|

Yes the thermal mass of a water heater solution makes it self-buffering, but why not the 100,000 BTU/hr Polaris? The combined load is managed by the volume of the tank, and even with the

heating system cycling during extended DHW draws it will have more burner output available for the

DHW load than a typical 40-50 gallon standalone gas water heater. The internal controls on the Polaris have a particularly tight differential (about 2-3F) and it IS possible to short-cycle them in space heating applications despite the thermal mass of the tank. There is an electronics hack that can be implemented that fixes that issue- just know that if violates the warranty once you start soldering on the thing. When using it for just the domestic hot water it doesn't short-cycle, since it's dealing with a slug of 40-55F water coming in, but in radiant heating systems you'll be feeding it 90-110F return water. If you're reluctant to give up the bigger burner, the HTP Versa Flame at least modulates between ~25K-130K, and gives you more buffering capacity to boot. It is better designed for micro-zoned combi heating apps than the Polaris or the glorified low-mass tankless HW heaters with "combi" in the product name. |

|

|

|

|

sailawayrb

Veteran Member

Posts:2272

|

| 21 Aug 2014 02:59 PM |

|

Very true, one should always evaluate the short-cycle potential of the HR heating system design to ensure that the heat source minimum cycle time requirements will not be exceeded. Heat pump manufacturers typically recommend a minimum of 5-10 minutes. Gas-fueled boiler manufacturers typically recommend a minimum of 10 minutes. Longer cycle times will typically result in higher heat pump Coefficient of Performance (COP) or boiler fuel thermal conversion efficiency. Electric-fueled boilers tend to not be bothered by short-cycle operation and typically operate at close to 100% thermal conversion efficiency even when short-cycled. You can use our buffer tank design software to accomplish this short-cycle analysis:

Borst Buffer Tank Design Software

We like the HTP Versa Flame too, but it is a higher cost option as compared to say the Navien. However, it can certainly be defended that you often get what you pay for. |

|

| Borst Engineering & Construction LLC - Competence, Integrity and Professionalism are integral to all that we do! |

|

|

BadgerBoilerMN

Veteran Member

Posts:2010

|

| 21 Aug 2014 07:54 PM |

|

We design and install combi water heating systems every day.

Heat load too high, loops too short and more flow than we use in three of our new house designs, but it will work.

As usual Dana is spot on and you have yourself a good match. DIY heat loads, regardless of the software (Radiant Works is fine) has it's pitfalls. If you focus on the big numbers e.g. infiltration, fenestration as Dana suggests, the minutiae so often touted here will be seen in the proper prospective.

I too would choose the Polaris and tie it to a subsystem (plate HX, pumps and ODR). The differential is too tight but cycling is nothing like an improperly applied combi-boiler. The Navien is no exception, with a minimum input of 20mbtu/h for the popular CH210 you have to avoid small zones as this input likely represents more than a third of your "total" design load.

Combi-boilers are difficult to fit in the average home loads, new or retrofit, unless the house is built around the heat source. |

|

| MA<br>www.badgerboilerservice.com |

|

|

ACES-Energy

New Member

Posts:67

|

| 25 Aug 2014 07:09 AM |

|

Not an answer..but what program did you use to draw your little drawing with?> |

|

| www.ACES-Energy.com |

|

|

| You are not authorized to post a reply. |

|

Active Forums 4.1

|

Membership: |

|

Latest:

Steve Toorongian |

|

New Today:

0 |

|

New Yesterday:

1 |

|

Overall:

34721 |

|

People Online: |

|

Visitors:

111 |

|

Members:

0 |

|

Total:

111 |

|

|

|