Hi everyone,

Hoping I could get clarification on a few expansion tank questions I had in addition to some feedback on moving the location of the expansion tank. Little background on my project. Its a closed loop radiant heat system running off of a A.O. Smith Vertex (100BTU).

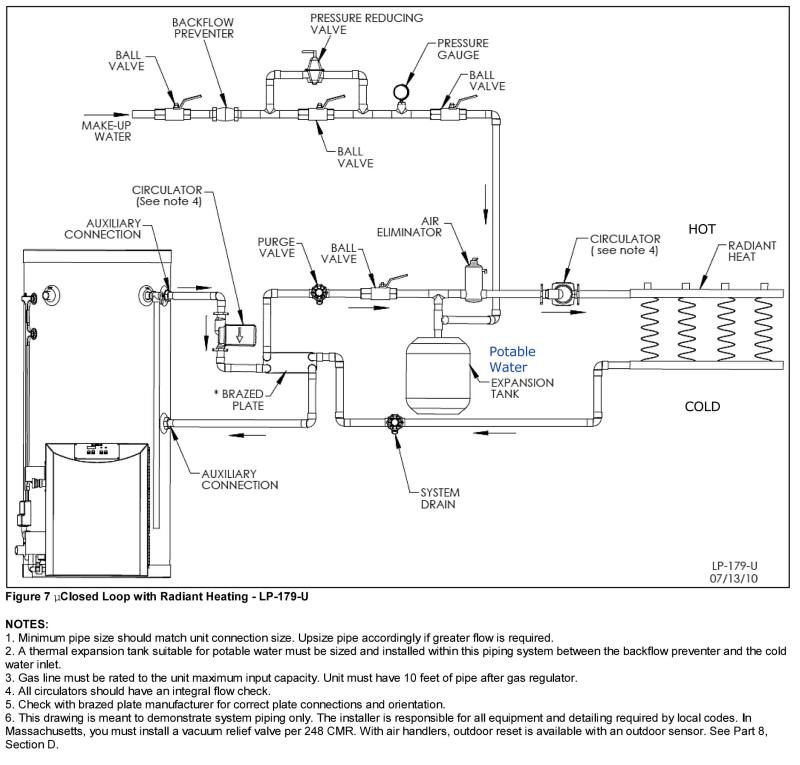

My plan calls for a "potable water" expansion tank near the cold out side of the manifold. The first diagram is from the phoenix manual. It is very similar to my heating diagram. Here the manual also states " A thermal expansion tank suitable for potable water must be sized and installed within this piping system between the backflow preventer and the cold water inlet".

Q: If the system is "closed" why is there a need for a potable water expansion tank? An atmospheric backflow preventer for example should stop any sort of backflow. The rest of the system to the right of the heat exchanger has no contact with the domestic water supply.

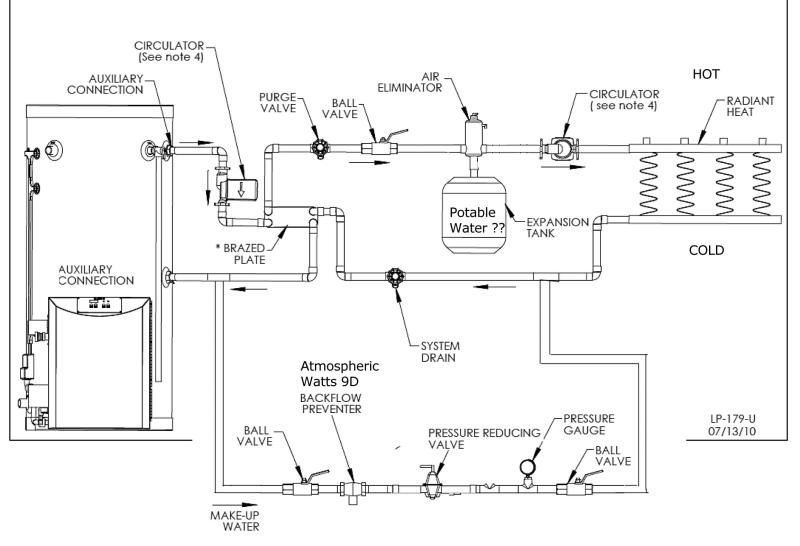

My manifold (rifeng) has air eliminator's built into the manifold, however I decided to get an Spirotherm Air Eliminator that has an expansion tank connection at the bottom. This is where my next expansion tank question comes into play. Is a "potable water" expansion tank still what I should be installing here? From my research, expansion tanks made for potable water purposes are not made to take constant hot water because of there construction.

I have attached a second drawing which shows the expansion tank below the air eliminator. The supply make up water coming off of the cold return line. A watts 9D atmospheric back flow preventer and then the fill valve aka pressure reducing valve (taco).

Thanks in advance!