thescottcav

New Member

Posts:46

|

| 11 Mar 2015 10:33 AM |

|

Hello, I have enjoyed the discussions on this forum, GBA and others while planning for my new construction (SW Ohio). I would appreciate some feedback on the wall design I am planning.

Exterior to Interior:

Brick > 1" airgap > 2" foam board > WRB (taped) > OSB (taped) > 2x4 stud wall with fiberglass or cellulose > drywall.

I am planning for the air barrier to be the taped OSB sheathing using tapes from 475 (or something similar). I am not sure what foam to use since it is not clear what affect the shrinkage factor has on the long term performance of the foam. I am considering EPS or XPS for the exterior wall foam and XPS for under the slab. From what I have read the 2" of foam is above the minimum we need to avoid condensation inside the wall. The HVAC contractor(s) we are considering are calculating their Manual J based on R-20 walls. Depending on the cavity insulation I may use an interior barrior like the Intello Plus.

We are planning for an HRV/ERV and getting the wall really tight is our goal. We'll also tape/seal the wall at the top and bottom/sill, windows and other penetrations. This is not a PassiveHouse but the goal is a Pretty Good House.

Question on the blower door test: I think this should be done with the ceiling drywall installed and penetrations sealed, as well as the walls and foundation taped and exterior foam installed? I assume we should wait for interior insulation and attic insulation until after the blower door test (to look for air leaks). Correct?

Any comments are appreciated-- I thank you in advance!

Scott |

|

|

|

|

|

|

Bob I

Veteran Member

Posts:1435

|

| 11 Mar 2015 11:11 AM |

|

use EPS under the slab - less expensive, far lower GWF & almost the same R value.

Do the blower door test while the walls are open - before they are insulated. If you drywall the ceiling prior to installing the interior walls (the ideal way) then you can use that as an air barrier. We install and tape a membrane on the ceiling before partitions go up for that reason. If you install the drywall after the partitions, there can be a lot of air leaks at the wall/ceiling which you will need to find. |

|

| Bob Irving<br>RH Irving Homebuilders<br>Certified Passive House Consultant |

|

|

Dana1

Senior Member

Posts:6991

|

| 12 Mar 2015 05:33 PM |

|

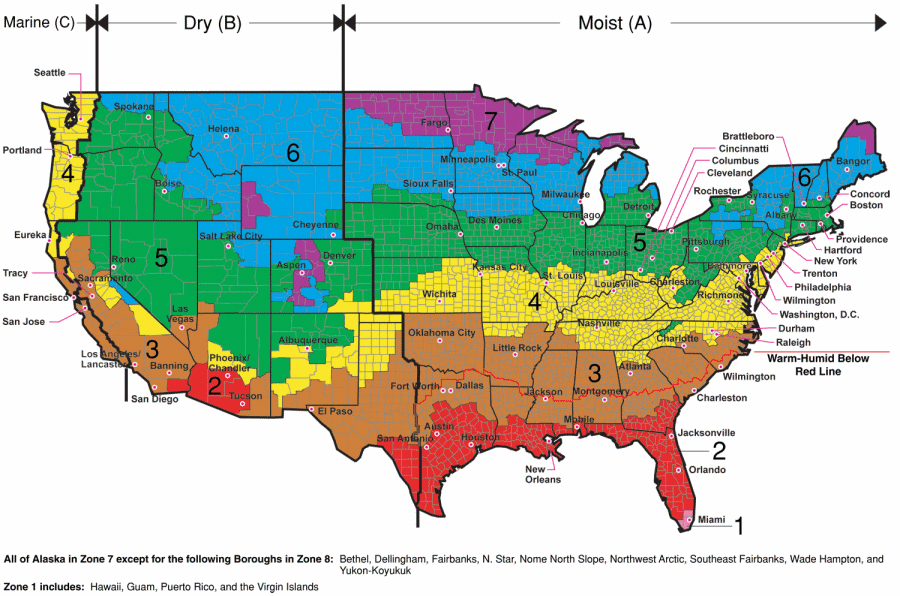

What climate zone is this? SW Ohio is on the bounadray of zones 4A/5A. You can hit R20 whole-wall more cheaply with 2x6 24" o.c. cellulose construction and 1.5" of exterior EPS (R6) or 1" of XPS (R5) than with 2x4 + R10 foam. R6 is more than sufficient dew point control for climate zone 4, and good even into the warmer third of zone 5. With a smart vapor retarder the interior you'd be fine even on the cold edge of zone 5, and it would still be necessary to meet the letter of code in Cincinatti, which is the very warmest edge of zone 5. Code requires R7.5 min for 2x6 construction in zone 5, only R5 for 2x4, which would allow you skip the expense of the smart vapor retarder. At 12-15 cents per square foot MemBrain is pretty cheap insurance- way cheaper than another inch of foam! Intello Plus is more than 2x as expensive as MemBrain though, and while it adds resilience, it doesn't cut the energy use the way an extra inch of foam would. If you're close to the margin it's worth doing the math.  |

|

|

|

|

thescottcav

New Member

Posts:46

|

| 13 Mar 2015 09:10 AM |

|

Dana,we are just north of Cincinnat and I am planning for Zone 5. Talking with our framers we determined the 2x4 wall with 2" of foam would be a more simple solution for construction than to do code min of R5 foam with 2x4 wall or to go to 2x6 and add foam, since the 2x4 wall plus 2" of foam has the same thickness as a standard 2x6 wall. My indecision with the smart vapor retarder is not a cost issue as much as I have not gotten that far determining the materials we'll end up using. Using them does seem like an easy decision.

Bob, Thanks for your comment as well. We'll definitely get the drywall contractors working on the ceilings before we do interior walls. Is the membrane as critical in ceilings that are vented? It makes sense in cathedral/unvented ceilings but in a well-vented attic is it necessary? |

|

|

|

|

Bob I

Veteran Member

Posts:1435

|

| 13 Mar 2015 09:40 AM |

|

the hardest places to air seal in a new house are ceilings; especially after the walls are built and you have hundreds of wires and pipes going through into the attic. You can air seal it from above after the fact with a lot of spray foam, but it can be difficult and somewhat expensive. So we've started installing an air barrier on the ceiling before we build the interior partitions; some builders use fabric, some plywood (ZIP) and some install drywall. Then, any wires or pipes can be pretty easily taped to the fabric, and there won't be gaps where the drywall meets the ceiling.

Air sealing is as important as insulating; you can build a well insulated house but if it's drafty it will not perform well and will be uncomfortable. It is especially important to seal a ventilated attic since the venting can pull air from the living space up & out. Whether or not you find the holes, air will find them. |

|

| Bob Irving<br>RH Irving Homebuilders<br>Certified Passive House Consultant |

|

|

Dana1

Senior Member

Posts:6991

|

| 13 Mar 2015 11:53 AM |

|

In a vented attic at the warm edge of zone 5 there's no point to a vapor retarder in the ceiling, but large format sheet roll goods can make air-sealing easier, as Bob alludes to. You can use anything from housewrap to smart-vapor retarders, but in your climate polyethylene sheeting would be a mistake, since your summertime outdoor dew points (and the dew point of the attic air) are likely to be above the ceiling temperature if you air condition, which would lead to condensation on the polyethylene.

From a design point of view it's sometimes easier to use OSB detailed as an air barrier on the under side of joists/truss-chords to support high-R attic insulation and use 2x4s below the OSB to create a utility chase for all of the wiring etc. This results in far fewer penetrations of the air barrier to deal with. If desired you can also insulate the chase cavity with batts or blown fiber to boost the R.

With 2" of exterior foam you'll get slightly better mid-winter performance out of a 2x4 wall if you put 1" of foil faced polyiso next to the sheathing, with 1" of EPS between the polyiso and siding. The reason this is so is that polyiso performance while quite high when the mean temp through the foam is 75F (the ASTM C518 test condition under which it is tested for R-value labeling), it peaks at a mid-foam temp of about 60F, but falls pretty fast when the mid foam temp is below 40F. The performance of EPS rises with falling temps so when it's below freezing outside an outer inch of of EPS will outperform an outer inch of polyiso, but the inner inch of polyiso would still be performing well, since the EPS is keeping it warm enough to be in a decent-performance zone. From a labeled-R point of view 2" of polyiso would run R12-R13, but during mid-winter coolth it would be runnign about R-8-9, averaging about R10 over the whole winter. With the 1" + 1" polyiso you'd have a labeled performance of R10-R11, and it would actually deliver that across the anticipated temperature range in Cincinatti. (It might fall slightly below that when it's -5F out during a Polar Vortex event, but not nearly as low as 2" of exterior polyiso would.) There isn't a lot of good derating performance out there for polyiso (the folks at Building Science Corp are currently working on that), so the modeling isn't perfect, but that's the rough-guesstimate based on what's currently been published.

With 2-layer foam it's worth taping the seams of both layers, and staggering the layers by about a foot so that normal temperature and aging shrinkage doesn't open up large air leakage & thermal short-circuits through those gaps. |

|

|

|

|

thescottcav

New Member

Posts:46

|

| 13 Mar 2015 04:30 PM |

|

Dana,

If I am planning to tape the OSB to create the air barrier do I also need to tape the foam? Does taping the foam still allow the wall to dry to the outside? Can the tape (the good ones!) handle the foam shrinkage? |

|

|

|

|

Dana1

Senior Member

Posts:6991

|

| 13 Mar 2015 05:05 PM |

|

Even though the OSB is your primary air barrier, it's still worth taping the foam. If you do a two layer foam with foil-faced polyiso as the middle of the sandwich it's pretty easy. Use a ~2" aluminum tape, purpose made for adhering to clean metal surfaces, with adhesives designed for long term use over a wide temperature range. Nashua 324A and 3M 431 are both widely available (even at box-stores & hardware stores) and suitable for this application. One is sold as a cold-temperature tape, the other a high temperature tape, but their service temp range (on both the hot and cold end) is well beyond anything you'd see in this application. If you use EPS with a plastic facer housewrap tape will cut it, but most EPS with facers is low density Type-I EPS (R3.9/inch instead or R4.2/inch), and it's pretty easy to break the stuff. Type-II EPS (1.5lbs nominal density, R4.2/inch) is more rugged. You can tape it with housewrap tape, but paint over it with 1/16-1/18" fiber reinforced duct mastic for better long term adhesion. There are rumored to be some European tapes designed for taping directly to EPS, but they don't seem to be available through the usual US outlets such as 475 High Performance Building Supply, etc.. |

|

|

|

|

jdebree

Basic Member

Posts:497

|

| 14 Mar 2015 06:37 AM |

|

I wanted to drywall the ceiling prior to putting up the internal walls, but it is not allowed here. You can't cover anything until after the electric/plumbing/mechanical is inspected, and the inspectors won't go up into an attic. Sure would have made life easier! |

|

|

|

|